|

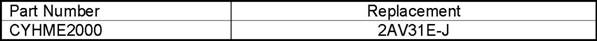

Hall-Effect Vane Sensor BBHME2000

(replaces 2AV31E-J)

DOWNLOAD PRINTABLE PDF HERE

INTRODUCTION

The Automotive Shaft Position Monitoring BBHME2000 is designed to work in the conditions of automobile environment. The device is produced in compliance with the international standard and features: modern design, accurateness, endurance, narrow temperature drifting, smooth and clean output curve as well as non instantaneous dithering.

It is applicable to engines with electronic ejection. The main applications are in automobile industry, i.e. as a breakerless trigger in electronic systems, in control engineering, especially in those areas where switches/ sensors must operate maintenance-free under harsh environmental conditions, e.g. rpm sensors, limit switches, position sensors, speed measurements, shaft encoders, scanning of coding disks etc.

The BBHME2000 is replacement of the similar product 2AV31E-J. They are compatible in electrical and mechanical properties but with different circuitry principle.

FEATURES

-

Contactless switch/sensor with open collector output (40mA)

-

Static switching/sensing

-

High switching/sensing frequency

-

Hermetically sealed with plastic

-

Unaffected by dirt, light and vibration

-

Large temperature and voltage ranges

-

Integrated protection of overvoltage etc.

The Hall Effect vane sensor BBHME2000 is a non-contact sensor/switch, which consists of a monolithic integrated Hall Effect circuit and a special magnetic circuit hermetically sealed in a plastic package. The sensor is actuated by a soft-iron vane passing through the air gap between magnet and Hall sensor.

MEASURING PRINCIPLE

The Hall Effect vane sensor consist of a Hall IC and a permanent magnet (SmCo, NdFeB disc or block), which are hermetically sealed in plastic (see the following figures). The sensor is actuated by a soft iron vane that passes through the air gap between the magnet and Hall IC. The open collector output is conductive (low) when the vane is outside the air gap (see Fig. a)), and blocks (high) when the vane moves into the air gap (see Fig. b)). The output remains high as long as the vane positions in the air gap. This is the so called static function. The output signal shape is in this case independent on the operating frequency.

Overvoltage is integrated in the circuit in order to protect against most of the voltage peaks occurring in automotive and industrial applications. The output stage has a Schmitt trigger characteristic. Most of electronic circuits can be driven directly thanks to the open collector output current of maximum 40mA.

MECHANICAL CHARACTERISTICS

The Hall Effect vane sensor is hermetically sealed in a special plastic package, so that it can also be used under harsh environmental conditions. The package is waterproof, resistant to vibration, gasoline, oil and salt. Two tubular rivets are incorporated in the package to mount the sensor on the carrier plate. The sensor has three leads for power supply, output and ground.

ABSOLUTE MAXIMUM RATINGS

|

Supply Voltage

|

30V

|

|

Reverse Battery Voltage

|

– 40V

|

|

Output OFF Voltage

|

40V

|

|

Reverse Output Voltage

|

– 0.5V

|

|

Output Current (at TA=25�C)

|

40mA for 5 minutes max

|

|

Operating Temperature Range

|

– 40�C~ +150�C

|

ELECTRICAL CHARACTERISTICS at Vcc=12V

|

Supply Voltage

|

4.5V~24V

|

|

Supply Current

|

≤9mA

|

|

Output Saturation Voltage(Sinking 20mA)

|

≤0.4V

|

|

Output Leakage Current

|

≤10uA

|

|

Output Rise Time

|

≤2uS

|

|

Output Fall Time

|

≤2uS

|

|

Output type

|

NPN (OC)

|

MECHANICAL PARAMETERS

|

Part number

|

De(mm) operation distance

|

Da(mm) release distance

|

|

Min

|

Typ

|

Max

|

Min

|

Typ

|

Max

|

|

BBHME2000

|

0.85

|

1.45

|

2.05

|

1.54

|

2.29

|

3.04

|

CROSS REFERENCE

Have a question? Click Here for assistence

|